plug flow reactor example

As the cracking chemistry is endothermic control over the temperature in the reactor is essential in order to achieve reasonable conversion. F A0 5 molmin.

1 4 Continuous Flow Reactors Elements Of Chemical Reaction Engineering Mole Balances Informit

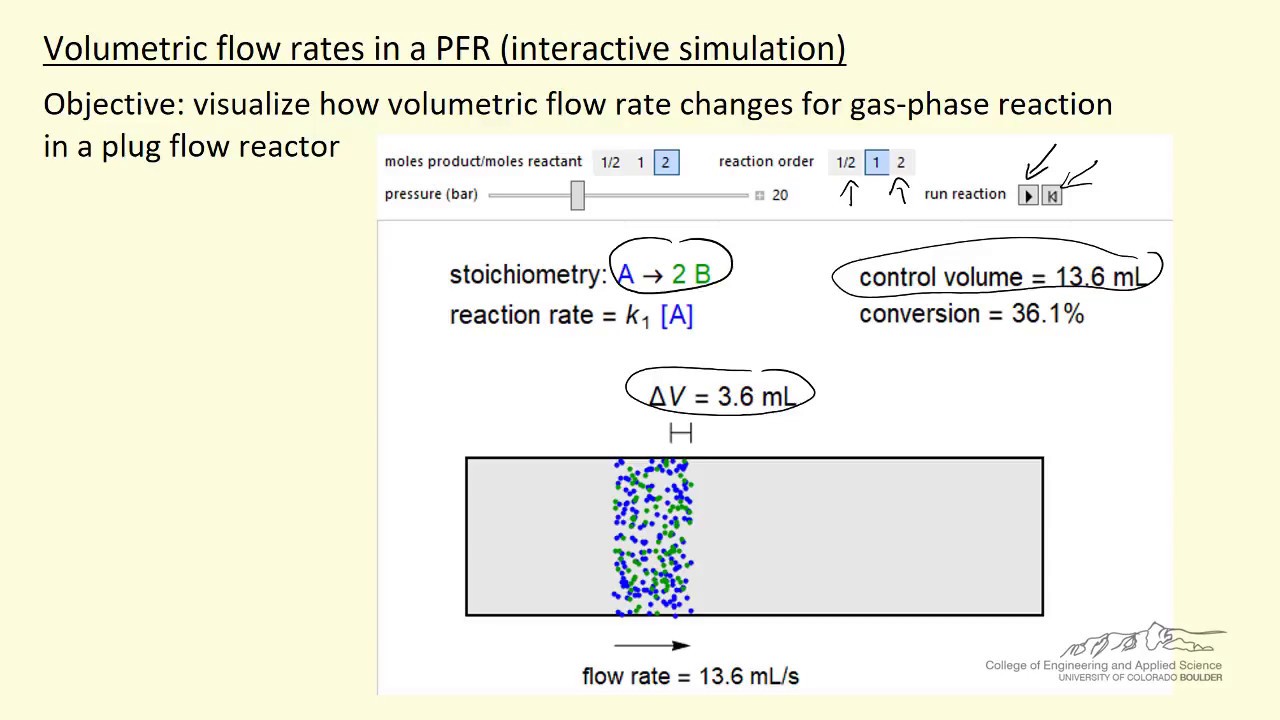

I work through how we can determine the required volume of a plug flow reactor PFR given a demanded outlet concentration conversion using the PFR design.

. Some examples of reactors include lakes rivers and sedimentation tanks. Import nextorch and other packages. A 2B 2D r A -25C A05 C B mol L -1 min -1.

These reactors will be discussed in more detail in the following sections. Ideal reactors and some real. Determine X e for a PFR with no pressure drop P P 0.

Normal butane C 4 H 10 is to be isomerized to isobutane in a plug-flow reactor. Examples of real reactors that approximate the flow pattern of ideal reactors are shown in Figure 10. Visualize the Pareto front.

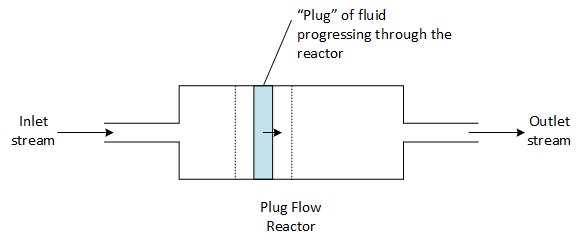

Define the objective function and the design space. Example 7 - Multi-objective optimization for plug flow reactor. A plug flow reactor PFR is a type of chemical reactor where the influent is pumped into the pipe.

The gas phase reaction takes place under nonisothermal conditions in a plug-flow reactor. Lecture 64 is focused on the simulation of the plug flow rea. Example 5 Application of Effectiveness For a second-order reaction in a plug flow reactor the Thiele modulus is SVQ and inlet concentration is C50 10.

The enzyme is immobilised in resin particles and packed into a 05-m 3 column. The volumetric flow rate of the feed is 50 Lmin. In fact real reactors can be modeled as networks or combinations of multiple plug-flow and stirred-tank reactors Towler and Sinnott 2013.

K 2 dm 3 mol-min. Kayode Coker in Ludwigs Applied Process Design for Chemical and Petrochemical Plants Fourth Edition 2015. ASPEN PLUS Example Problems.

The plug flow tubular reactor is a heat exchanger in which the reaction occurs in the tubes. For example the reactor may consist of a tube placed in a bath a tube in a jacket or a. This example considers the thermal cracking of acetone which is a key step in the production of acetic anhydride.

The feed enters at 330 K. C A0 02 moldm 3. K C 100 dm 3 mol.

The equation will he integrated for 80 percent conversion with Simpsons rule. This elementary reversible reaction is to be carried out adiabatically in the liquid phase under high pressure using a liquid catalyst which gives a specific reaction rate of 311 h-1 at 360 K. AspenTech channel has brought another exciting video for its valuable viewers.

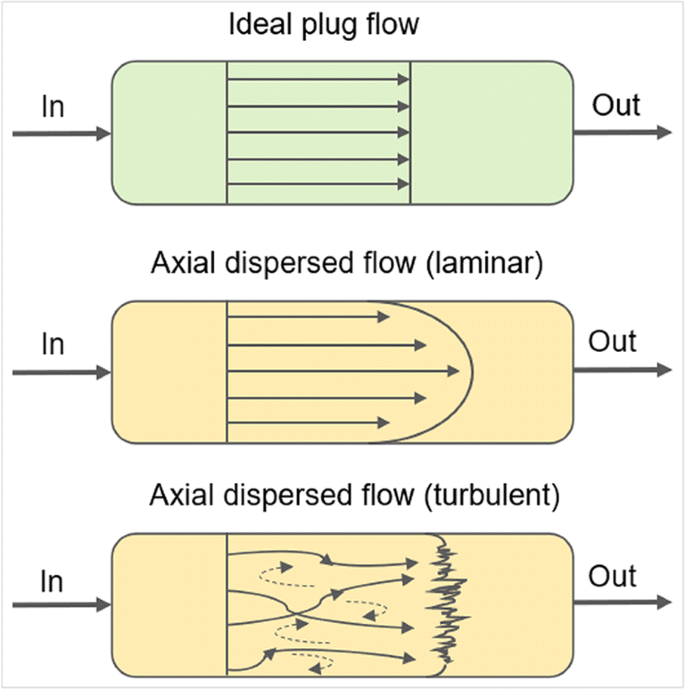

Other simplifications used are perfect radial mixing and a homogeneous. Given that the system is gas phase and isothermal determine the reactor volume when X 08 X e. The degree of mixing and residence time in reactors affect the degree of completion of reactions within the reactor.

The same example problem has been worked in Aspen and Matlab. Plug flow reactor simulation in example 8 4 H scott Fogler. The reaction is gas-phase in an isothermal PFR and is at 50 atm pressure and 55C.

One example is in the design of chemical reactors. Develop equations to determine plug flow reactor size for 50 conversion of reactant A. Plug Flow Reactor for Immobilised Enzyme.

This results in differential equations that need to be integrated to find the reactor conversion and outlet temperatures. The pressure difference between upstream 1 and downstream 2 reservoir is defined as P_1 - P_2It is never possible for the flow to reverse and go from the downstream to the upstream reactorreservoir through a line containing a Valve object which means that the flow rate is set to zero if P_1 P_2. Continuous Isothermal Plug Flow Tubular Reactor.

Plug flow reactors are unique in the sense that operation in parallel or series give the same conversion if the space time is held constant. Valve objects are often used between an upstream reactor and a. Plug Flow Reactor Example This example will take you through the entire process of setting up multiple reactions and creating a plug flow reactor in HYSYS as shown in the picture above.

Define the initial sampling plan. Essentially no back mixing is assumed with plugs of fluid passing through the reactor. The plug flow model has many practical applications.

This implies for example that if a 20-m reactor of fixed diameter is required to achieve a given conversion the same conversion and capacity can be achieved by running ten 2-m reactors in series or ten 2-m. Initialize an Experiment object. Their construction is varied.

Example 9 - Multi-objective optimization for Microwave operating conditions. IIIC3ai Plug flow reactors. Immobilised lactase is used to hydrolyse lactose in dairy waste to glucose and galactose.

Reactor Design And Selection For Effective Continuous Manufacturing Of Pharmaceuticals Springerlink

Volumetric Flow Rates In A Plug Flow Reactor Interactive Simulation Youtube

Plug Flow Reactor Vapourtec Ltd

Mole Balance On A Plug Flow Reactor Youtube

Variable Density Reaction In A Pfr Youtube

Isothermal Plug Flow Reactor Part 1 Youtube

Plug Flow Reactor Pfr Sizing And Conversion Example Youtube

Deviation From An Ideal Flow Pattern Part 1 Petroleum Refining

Plug Flow Reactor An Overview Sciencedirect Topics

Plug Flow Reactor With Ramped Flowrate Modelled As A Series Of Download Scientific Diagram

Background Continuous Reactor Hydrodynamics

Plug Flow Reactor Overview Youtube

Sizing A Plug Flow Reactor Pfr Youtube

Experimental Setup Of The Plug Flow Reactor With Tof Ms Download Scientific Diagram